Extreme Lab Makeover

text

Friday, 12 February 2021

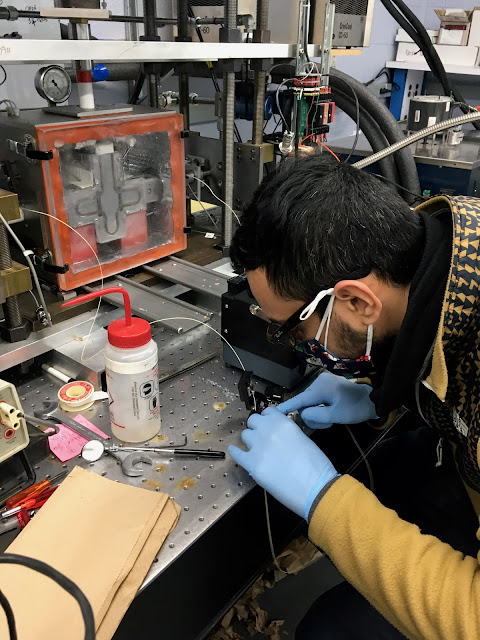

Tether testing with Vishaal

Tuesday, 1 September 2020

Final Install on the AutoLab

This week the guys from New England Research (NER) came out to do the final install on our AutoLab2000 HPHT. The biggest task was to get that big pressure cell, which has been sitting in a big crate in the middle of the prep room for a few months, into the rig.

Not an easy feat. They decided to use the multi-ton overhead crane in the main lab. Eyebolts on the top of the pressure cell made it easy to lift.

Monday, 10 August 2020

It moved!

A lot has progressed in the lab since we first started ramping back up in early July. One major development is that we moved the ice rig. Step one was to disconnect all of the wiring and hydraulics from the frame.

Meanwhile, Jake and Ted were back in the new lab, prepping the anti-vibration table, making sure it was perfectly horizontal and up against the back wall.

Monday, 11 May 2020

New Walk In

Before the lockdown, we were *this close* to getting our own walk in freezer set up. It will also be housed in the Instruments building, so no more walking across campus in the rain with samples. A room in the back corner of the warehouse was cleared out and the floor given a nice paint job. That's gray with specks of different shades of blue. We taped off the location for the walk in and awaited its arrival from culinary depot. It arrived stacked nicely on a pallet and the refrigeration team went ahead with installation.

I walked away late morning to attend a meeting and by the time I returned it was already assembled. They were so fast!

Tuesday, 14 April 2020

Extreme makeover gets even more extreme: Part 2, the prep room

First task was to break down everything metal, clean it, sand it and paint it black. Starting to look good.