Time to take a long overdue lab photo. Here is the rock mechanics team.

text

The rock and ice mechanics lab at Lamont-Doherty is led by PIs Christine McCarthy and Ben Holtzman. Now, more than ever, we are in the process of growing our lab and building our experimental program. Along with a team of postdocs, undergrads, grads, techs, and longtime staff engineer Ted, we are rehabilitating and revamping some of the old equipment and building and buying new rigs for exciting new experiments on both rock and ice. You can follow along with our progress here.

Thursday, 21 November 2013

Thursday, 23 May 2013

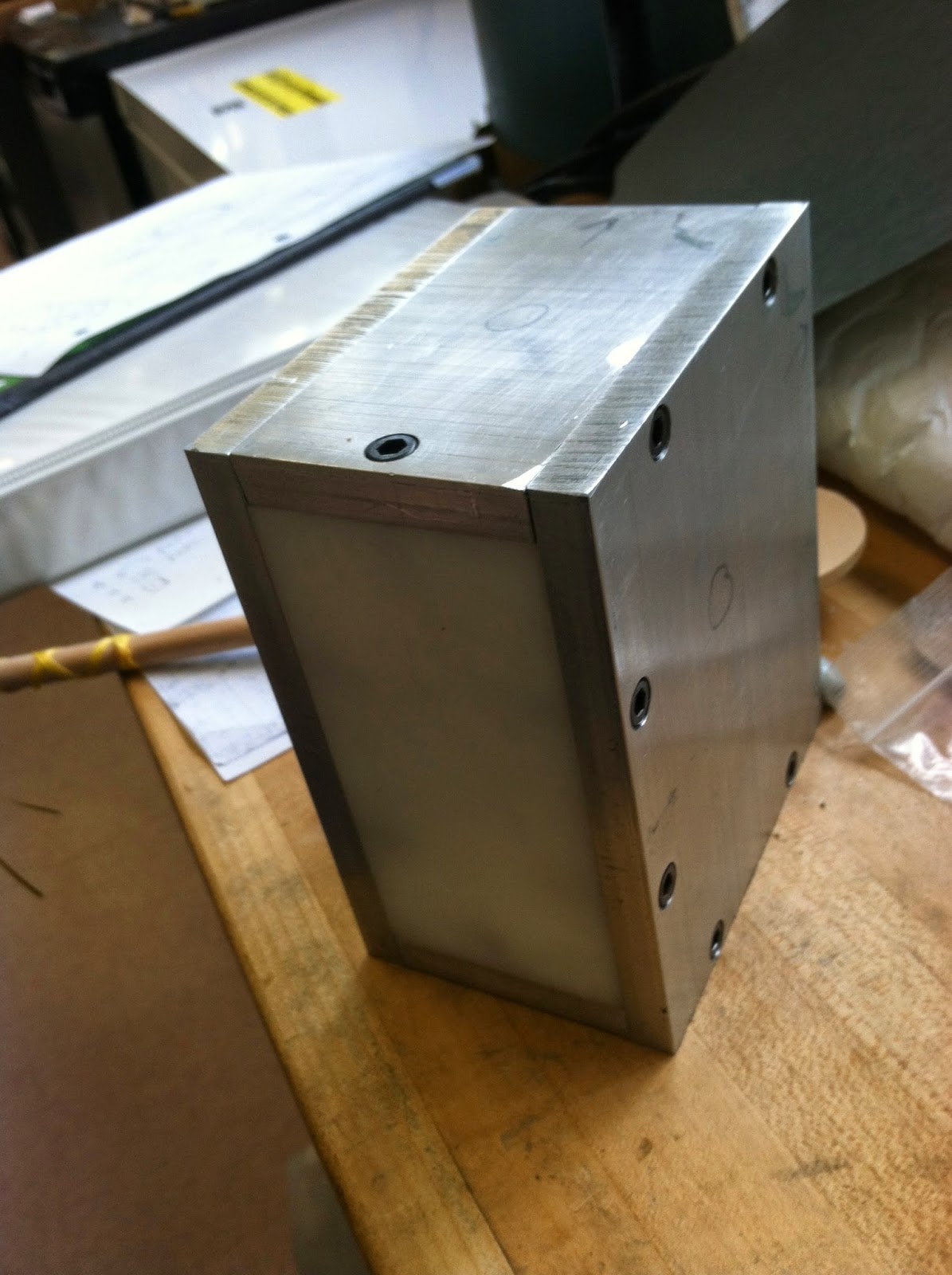

a bun in the oven; a sample in the freezer

The box has stainless steel sides but a teflon bottom, so that we can undo the screws and push the ice sample and teflon out of the can.

The top plate of the can has two ports: one for a vacuum and one to flood the sample with zero degree water. Beneath the top plate is a layer of teflon with a square o-ring that fits snuggly into the the top of the can. Fine-grained seed ice is packed into the can and then the lid pushes down and packs it more firmly while a vacuum pulls out excess air. Cooled water is then flooded into the pore space and freezes into a fully dense sample. All of this is done in a cold room that we now have access to.Thursday, 25 April 2013

Ice rig frame is assembled

Once we finally got the aluminum plates back from the machine shop, it was all hands on deck to assemble the ice rig frame. Here Hannah and I tighten the unistrut base and assemble the frame.

Next came the tie rods, middle supporting beams and the top aluminum plate. Had to make sure everything was level and lubed up.

A little while later, undergrad lab assistant Ben attached homemade brass bolts to which we will attach side plates (which the horizontal ram will need to push off of). He's hammering the top plate to get it in just the right position.Saturday, 26 January 2013

changing a gasket

So we've been suspecting for awhile that the vertical hydraulic piston on the biax might be leaking. Now that Nicholas has arrived to really start plugging away on some experiments, it became apparent that it needed fixing. Ted figured that we needed to change a gasket, which is no small feat. This week Ted and Nicholas slung a pulley system over a beam in the ceiling and carefully lifted out the cylinder.

Inside that big yellow cylinder lives a whole series of concentric rings that fit together to form the seal. Ted and Nicholas inspected them all carefully. Most of them were all still in great shape, despite some forty odd years of usage. But one piece in particular was torn to shreds. They replaced the part, lugged the cylinder back up and reattached it to the biax frame.Friday, 11 January 2013

Post-holiday activities in the lab

There has been a flurry of activity in the rock mechanics lab now that we are all back from the holiday. Hannah has been making big strides in the paleothermometer project, cranking out up to four experiments per day. Next she will analyze the samples in the mass spectrometer.

And although Mandy had to return to Germany, Heather has been continuing to put jackets on her granite samples in anticipation of Mandy's return later this year. Those copper jackets (left) have to be pressed onto the sample by bringing both up to 60 MPa in the triax. The blue plastic makes a seal to hold the pressure internally. And finally, I continued to work on the electronics for the ice rig by creating yet another panel. This one will allow us to splice into the signal coming from each of the load cells and LVDT, which will be extremely helpful once we start troubleshooting the apparatus.

And although Mandy had to return to Germany, Heather has been continuing to put jackets on her granite samples in anticipation of Mandy's return later this year. Those copper jackets (left) have to be pressed onto the sample by bringing both up to 60 MPa in the triax. The blue plastic makes a seal to hold the pressure internally. And finally, I continued to work on the electronics for the ice rig by creating yet another panel. This one will allow us to splice into the signal coming from each of the load cells and LVDT, which will be extremely helpful once we start troubleshooting the apparatus.

Subscribe to:

Posts (Atom)